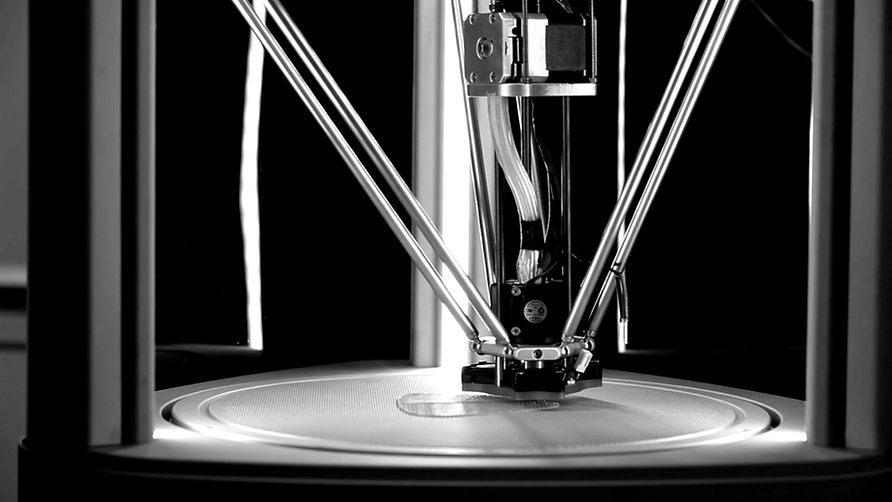

We’re accelerating additive manufacturing in Kentucky and surrounding regions.

NSF Engines Development Award: Advancing Manufacturing and Building Construction Technologies (NSF AMT)

We’re accelerating additive manufacturing (AM) in Kentucky and the surrounding region to advance U.S. domestic manufacturing and revitalize economic growth.

With an NSF Engines Development Award, we’ve set out to realize the full promise of industrial additive manufacturing. We’re transforming existing and new U.S. small and medium manufacturers into a twenty-first century network of AM suppliers creating a new engine for economic growth in the Heartland of America.

This requires real demand for additive manufacturing components, exponential advances in AM processes, technology, materials and qualification, robust workforce development and expanded access to capital for small and medium businesses.

Why Additive Manufacturing?

Potential of Additive Manufacturing

With the right research agenda, the translation of that research into practice, and the right workforce, AM will transform our nation's supply chain and lead to substantial economic growth in our region.

Growth of the Additive Manufacturing Market

The additive manufacturing market is rapidly growing, with an expected growth of $60 billion in the next decade on its current technology trajectory. Yet, AM can deliver much more.

Impact of Additive Manufacturing

Additive manufacturing supplies more reliable components for complex, next-generation applications, while producing less waste and using less energy. Applications include aerospace, defense, automotive, energy, semiconductor manufacturing, healthcare and consumer goods.

Kentucky's Commitment to Accelerating Innovation

In Kentucky, we know everyone wins when we work together.

That's why core institutions behind each of Kentucky's three NSF Engines proposals are committed to collaboration so we can boost Kentucky’s competitiveness and realize the commonwealth’s potential as a center for innovation.

Our commitment to collaboration was recognized by the Kentucky General Assembly in House Resolution 13 and Senate Resolution 27, pledging support for each proposal.

Research Concentration Areas

Our initial review of our regional manufacturing landscape identified three key research areas that can lead to additive manufacturing transformation.

1

Defense Supply Chain Resilience through Materials Advancement

2

Sustainability through AM Processes

3

Commercially Viable Design for AM (DfAM)

While these areas provide a solid foundation for amplifying the power of additive manufacturing, we need to better understand the hurdles to expanding the additive manufacturing applications into higher volume applications through small/medium manufacturing suppliers, large original equipment manufacturers and the research ecosystem. During our development phase, we will identify:

Technical hurdles (hardware, materials, data management, quality systems, maintenance challenges, etc.)

Small and medium business development hurdles (capital requirements, financing, margin management, etc.)

Small and medium business workforce hurdles (from shop-floor workers, to equipment maintenance staff, to engineers and quality-assurance coordinators)

Original equipment manufacturers and research workforce hurdles (engineers, material scientists, data scientists)

Core Values

News